Have you ever wondered why your automatic vehicle idles smoothly at a complete stop without the engine stalling? This article explores the torque converter function, detailing how this hydraulic device allows the engine to spin independently from the stationary wheels. We examine the internal mechanics that not only prevent the car from stalling but also multiply torque to deliver the powerful, seamless acceleration you rely on daily.

Inside the Box: The Core Components of a Torque Converter

The Engine’s Partner: The Impeller

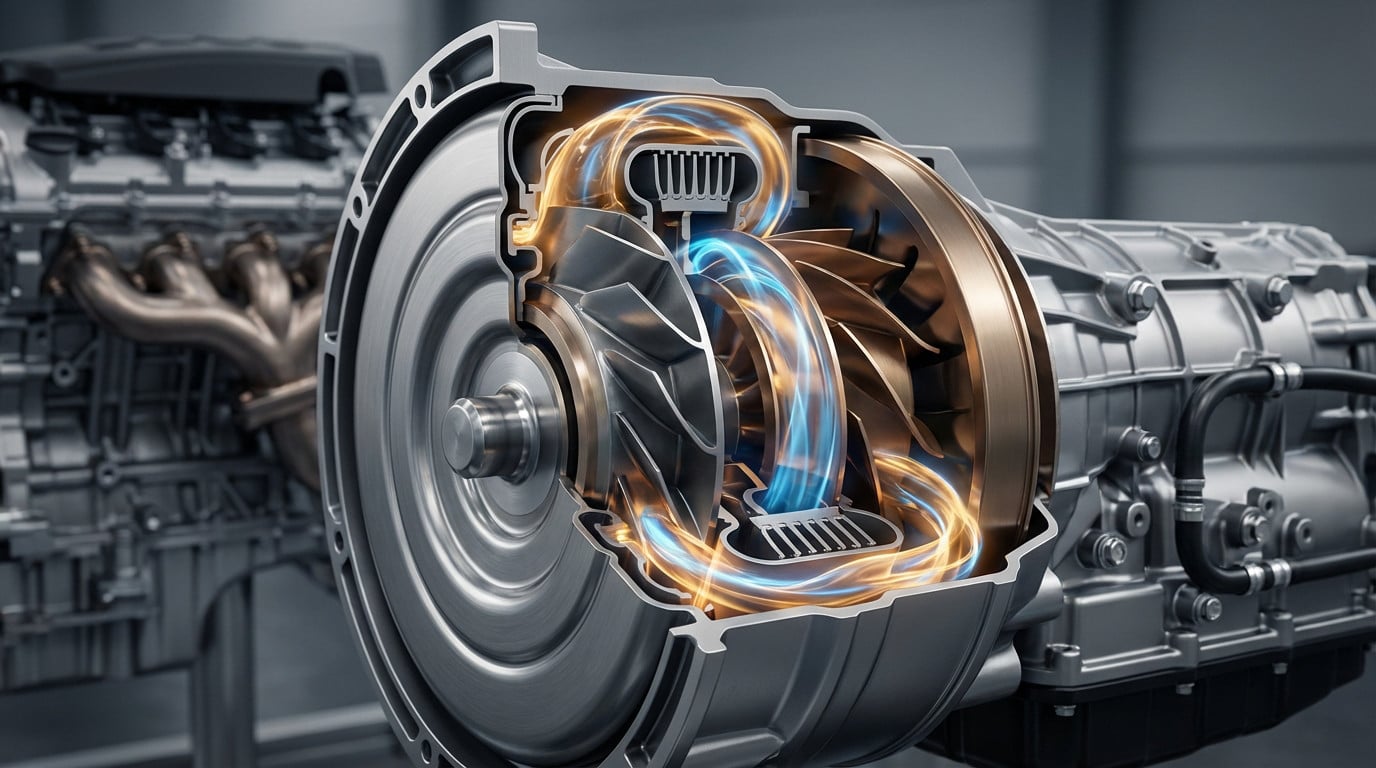

To grasp the torque converter function, look inside the heavy-duty housing between the engine and transmission. The first piece of this mechanical puzzle is the impeller, or pump. It starts everything.

Engineers bolt the impeller directly to the engine’s flexplate. Consequently, when your engine spins, this component spins alongside it. Its sole purpose involves pumping fluid inside the converter. It behaves exactly like a centrifuge.

This component sets all that raw energy into motion. It initiates the flow.

The Transmission’s Input: The Turbine

Facing the impeller, we find the turbine sitting in wait. Surprisingly, it holds no physical connection to the pump. They remain separated by a gap.

The turbine is splined securely to the automatic transmission input shaft. Fluid projected by the impeller strikes the turbine’s angled blades. This force compels it to spin. Finally, power reaches your wheels.

The Unsung Hero: The Stator and the Fluid

The stator sits centrally between the impeller and turbine. This small component makes the real difference.

The entire assembly bathes in specialized transmission fluid. This liquid does far more than lubricate parts. It serves as the medium transferring energy.

We can summarize the basic composition of a torque converter with these four key elements:

- The Impeller (the pump)

- The Turbine (the receiver)

- The Stator (the multiplier)

- The Fluid (the messenger)

It operates as a hydraulic coupling composed of these elements to effectively manage power delivery.

The Fluid Dance: How Power Is Transferred and Multiplied

A Simple Fan Analogy: The Hydraulic Coupling Principle

Picture two fans facing each other. You plug one in—the impeller—while leaving the other—the turbine—unplugged.

Air from the first spins the second. That is the basis of hydraulic coupling. In cars, transmission fluid replaces air, transferring power much more efficiently.

The Stator’s Trick: Achieving Torque Multiplication

Without a stator, fluid returning from the turbine would strike the impeller against its rotation, slowing the engine.

Mounted on a one-way clutch, the stator captures this “wasted” fluid. Its angled blades redirect the flow, pushing the impeller forward instead of fighting it.

This redirection fuels torque multiplication. Hydrodynamic converters maximize performance by doubling or tripling your engine’s force right when you hit the gas.

The Three Phases of Operation

The unit operates in three distinct phases: Stall, Acceleration, and Coupling.

The table below details the torque converter function in each scenario, showing how components adapt to keep you moving.

| Phase | Impeller vs. Turbine Speed | Stator Function | Result |

|---|---|---|---|

| Stall (Vehicle Stopped) | Impeller spinning, Turbine stopped | Locked by one-way clutch, redirecting fluid | Maximum torque multiplication, engine runs without stalling |

| Acceleration | Large speed difference | Locked, redirecting fluid for torque multiplication | High torque sent to transmission for strong acceleration |

| Coupling (Cruising Speed) | Speeds are nearly identical (approx. 90% match) | Freewheeling with the fluid flow | Minimal torque multiplication, direct power transfer (especially with lock-up) |

From a Standstill to Cruising: The Converter in Action

At the Red Light: The ‘Stall’ Phase Explained

You are sitting at a red light with your foot firmly planted on the brake. The engine hums at idle, yet the car isn’t moving an inch. This specific mechanics call the stall phase.

Inside the casing, the impeller spins slowly, sending just enough fluid force to make the car creep if you let go. The stator remains locked tight, waiting to multiply torque the second you need it. This defines the core torque converter function: keeping the engine alive while stopped.

Green Light Go: Acceleration and Peak Multiplication

The light turns green, so you hit the gas. Your engine RPM spikes immediately, causing the impeller to pump transmission fluid with serious aggression. At this exact moment, the speed difference between the spinning impeller and the stationary turbine hits its maximum.

Here is where the stator does its heavy lifting. It redirects the returning fluid to slam back into the pump, creating a massive boost. We call this the multiplication of torque, and it delivers that solid, punchy acceleration you feel right off the line.

Hitting Highway Speed: Coupling and the Lock-up Clutch

Once you reach cruising speed, the turbine has almost caught up to the impeller’s rotation speed. The fluid flow stabilizes, meaning it no longer needs aggressive redirection to keep things moving.

The stator then disengages its one-way clutch. It begins spinning freely with the rest of the assembly to reduce drag.

To stop any wasted energy, modern systems engage a lock-up clutch. This mechanism creates a solid 1:1 mechanical link between your engine and transmission. It is a smart fix for efficiency losses that would otherwise burn extra fuel.

The Trade-offs: Efficiency, Performance, and Modern Solutions

Nothing is perfect, and the torque converter involves compromises, though engineers have found clever workarounds.

The Cost of Convenience: Slip, Heat, and Fuel Use

You might not realize it, but that smooth idle has a cost: slip. Since the coupling is fluid rather than solid, energy vanishes during acceleration phases. This lost energy doesn’t just disappear; it transforms into heat, the transmission’s worst enemy.

That wasted energy hits your wallet. Compared to a stick shift, automatics often burn more gas, especially in city traffic. Since the torque converter function relies on fluid dynamics, the engine works harder to bridge the gap between idle and motion.

- The trade-offs are distinct: smooth starts, torque multiplication, and engine protection.

- Conversely: efficiency losses, heat generation, and a negative impact on fuel consumption.

Pushing the Limits: ‘High-stall’ Converters for Performance

Performance junkies hate waiting. That’s where “high-stall” converters come in. The “stall speed” is simply the specific RPM where the converter *locks up to deliver maximum torque transfer*.

By raising this limit, a high-stall model lets the engine scream to a higher power band before the tires turn. It’s the secret weapon for drag racers needing an explosive launch rather than a gentle commute.

The Modern Approach: Smarter Transmissions

The lock-up clutch was the first fix, physically bonding the engine to gears at speed. But modern boxes go further. Using 8, 9, or even 10 speeds allows the engine to hum exactly where it’s most efficient.

Designs have evolved, too. Flatter profiles reduce weight. These tweaks are significant car reliability factors extending vehicle life. Recent data on geometric optimization proves we can finally have comfort without sacrificing efficiency.

When Things Go Wrong: Spotting a Failing Torque Converter

Even the toughest torque converter wears out eventually. Knowing the early warning signs saves you a massive headache later.

Common Symptoms You Can’t Ignore

You usually feel torque converter issues before you see them. The car acts sluggish or sounds completely wrong.

When the primary torque converter function begins to fail, keep an eye out for these specific red flags:

- Shuddering or vibrations: A distinct trembling sensation, specifically hitting constant speeds between 30 and 45 mph.

- Slipping: Your engine revs climb high, yet the vehicle speed barely increases proportionally.

- Strange noises: You hear rattling, grinding, or whining sounds coming from the transmission area.

- Transmission overheating: A failing unit generates massive heat, cooking the fluid and ruining the gearbox.

Pinpointing the Problem: Potential Failure Modes

Stator failure is a frequent culprit here. If it sticks open, you lose torque multiplication instantly. That makes acceleration feel incredibly sluggish off the line. Conversely, if it locks fixed, your high-speed efficiency just collapses.

Other internal components break down eventually too. A bad lockup clutch causes that nasty shuddering sensation. Worn bearings often lead to loud grinding noises. Damaged seals will let vital fluid leak out rapidly.

What It Means for Your Vehicle’s Health

Ignoring these signs is a terrible strategy. Excessive heat cooks your transmission internals quickly. Metal debris then destroys exactly what remains.

You really need to stay vigilant on the road. Technology isn’t perfect, just as an ADAS can malfunction in bad weather conditions. Understanding your car’s mechanical alerts ensures your safety. It keeps your ride reliable for years.

Ultimately, the torque converter acts as the unsung conductor of our driving experience, seamlessly blending power and motion. By grasping its hydraulic principles and monitoring for wear, we ensure that this intricate dance of fluid dynamics continues to deliver the smooth performance we expect.